025-5821-8016

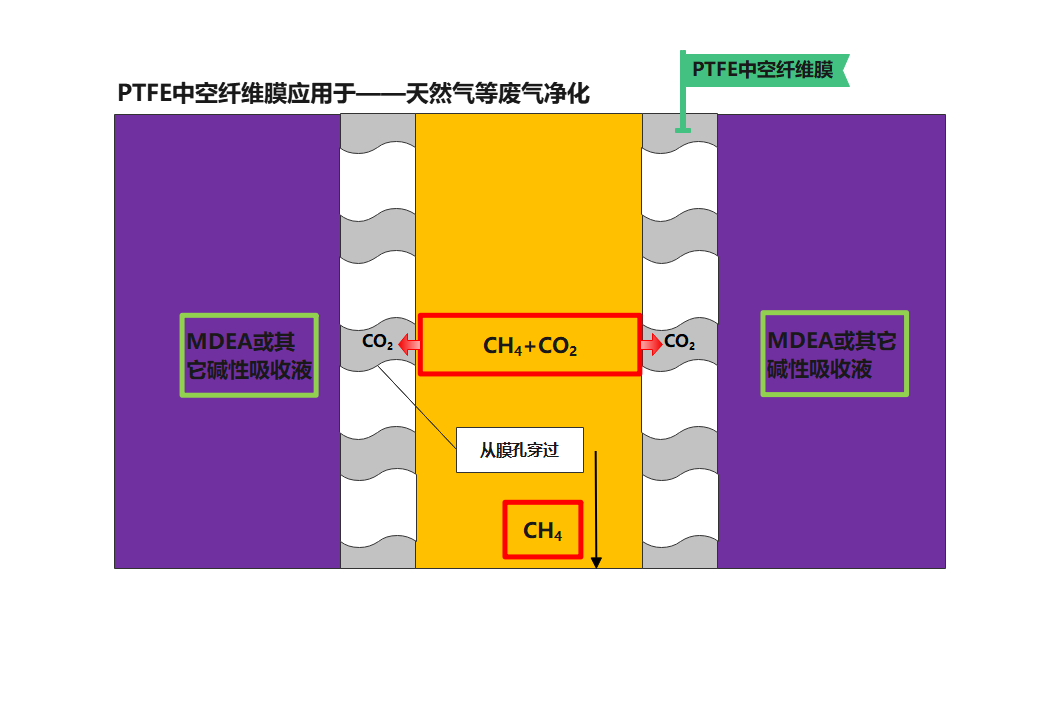

The extracted natural gas is often accompanied by acidic gases such as carbon dioxide and hydrogen sulfide, which need to be purified to reach commercial standards. Traditionally, scrubber process is used for natural gas purification, which has a large volume (loading density: 100-250 m2/m3), small operating elasticity, gas-liquid ratio fluctuation, easy to appear bubbling, flooding, flooding tower, high renewable energy consumption, inappropriate high CO2 content conditions and other problems, in order to overcome the above problems can use PTFE gas film material itself high permeability and high hydrophobicity, made of natural gas purification components as the core of the natural gas purification device. Natural gas purification by membrane absorption principle. The process has a high filling density (filling density: 1000-2500m2/m3, more than 10 times of the traditional scrubber), the volume is greatly reduced, the use of film as the gas-liquid interface to avoid flooding, flooding tower, bubbling and other phenomena, significantly improve the operating flexibility. This technology belongs to the category of carbon capture technology, and can also support the local carbon dioxide analysis and storage equipment to help China achieve the double carbon goal. The mass transfer mechanism is shown in the above figure.