025-5821-8016

I. Core technology

Membrane absorption deamination technology is a new type of efficient deamination technology that combines physical or chemical absorption and membrane separation. Firstly, a certain amount of alkali is added to the ammonia wastewater to adjust the pH value, ammonia nitrogen has a dissociation equilibrium in water, as the pH rises, ammonia dissociation occurs in water, when the pH is higher than 11, 98% of the ammonia in the wastewater is dissociated into the free state of NH3. After adjusting the pH value, the dissociated ammonia wastewater and the dilute sulfuric acid absorbing solution enter into the tube and shell processes of the membrane contactor, respectively, and since the ammonia in the wastewater is dissociated into NH3, NH3 will gradually evaporate from the gas-liquid interface, and diffuse through the hydrophobic porous membrane. As the ammonia in the wastewater has been dissociated into NH3, the NH3 will be volatilized from the gas-liquid interface gradually, and diffuse through the membrane holes of the hydrophobic porous PTFE membrane into the dilute sulfuric acid to be absorbed. The microscopic reaction process is shown in Fig.

Reaction sketch of membrane absorption process for high ammonia wastewater

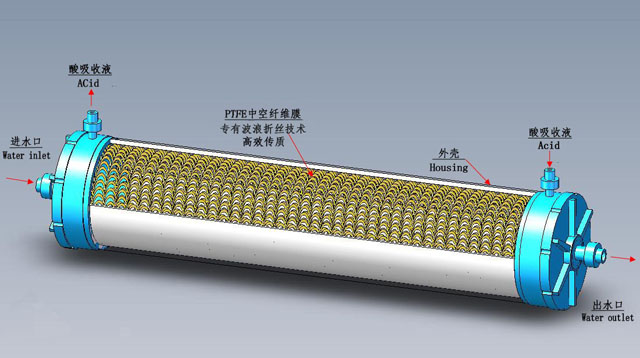

The hydrophobic PTFE membrane with hollow fiber structure has a very high specific surface area and provides a mass transfer interface for two-phase mass transfer. Due to its good hydrophobicity and chemical stability, PTFE membrane has a long service life and stable performance compared to other membrane materials such as PP or PVDF.

In the traditional blow-off process, the high ammonia nitrogen wastewater after alkali dissociation first into the blow-off tower, using a large amount of compressed air for blowing off, after blowing off the exhaust gas into the acid absorption tower to absorb the ammonia in the exhaust gas, so as not to enter the atmosphere to pollute the environment.

In the membrane absorption process, the membrane contactor complete replacement of the blowing tower and desorption tower function, will be combined into a membrane contactor as a whole, in the membrane contactor, can be carried out at the same time the ammonia desorption and absorption process, due to the membrane contactor in the PTFE hollow fiber membrane for the structure of the filaments, the contact area is large, the reaction efficiency is improved, and can greatly reduce the footprint of the equipment. In addition, because the membrane absorption process does not use the air blowing off, so it will not bring the process of secondary pollution, has a strong technical advantage.。

Hollow Fiber Membrane Filament and Membrane Module

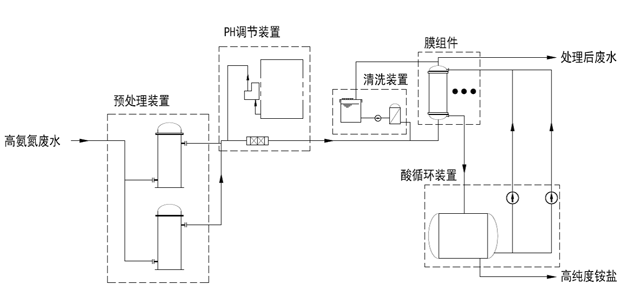

High ammonia wastewater treatment system includes pretreatment device, PH adjustment device, membrane module, acid circulation device, cleaning device, the above system devices through the supporting piping, valves and instrumentation connected to form a set of high ammonia wastewater resource treatment system, the system process flow is shown in the figure below.

High ammonia wastewater membrane absorption process flow chart

Second, technical characteristics

Membrane absorption method of ammonia removal technology is mainly characterized by:

(1) High mass transfer driving force and high ammonia nitrogen removal efficiency. The absorption of ammonia in the absorbing liquid is a rapid reaction, and the concentration of free ammonia on the absorbing liquid side is strictly zero, which provides the maximum impetus for the mass transfer process, so that the ammonia and nitrogen in the wastewater can be effectively removed to below the national permissible emission standards or the specified concentration.

(2) In addition to sulfuric acid, the absorption solution can also be hydrochloric acid, nitric acid, renewable absorbent, etc., the corresponding by-products of ammonium chloride, ammonium nitrate, ammonia, etc., by-products of higher concentration and purity, can be reused or exported to reduce the cost of wastewater treatment.

(3) Modular skid mounted form, small footprint, flexible and convenient operation, can be adjusted according to the site water quality system configuration.

(4) When the traditional vapor extraction or blowing off process needs to adjust the pH value of wastewater, generally can not use slaked lime, only use NaOH, this is because the vapor extraction process with the rise in temperature Ca (OH) 2 solubility reduces the precipitation from the wastewater, blowing off the process of wastewater Ca (OH) 2 and the reaction of CO2 in the air to generate insoluble CaCO3, which can cause scaling of the tower pieces and the blockage of the tower, affecting the service life of the equipment and the clogging of the tower. All of them can cause fouling of the tower parts and clogging of the tower, affecting the service life of the equipment and normal operation, even if the use of anti-fouling tower parts need to be frequently cleaned tower equipment. Stabilized film absorption process material does not need to contact with the air, so there is no such problem, and thus can use lime to adjust the pH value of the solution, so that the operating costs are greatly saved.

(5) Ammonia in the wastewater into the ammonium in the absorption solution just need to pass through a layer of 200 microns thick hydrophobic membrane, do not need to drum up a lot of air contact with the wastewater and in the closed system, so there is no wastewater in the toxic odor components are blown into the atmosphere, thus avoiding the secondary pollution, has a great deal of environmental benefits.

(6) The PTFE membrane is corrosion-resistant, acid and alkali resistant and stable in operation.

Application cases

The process system has been applied in a vanadium mining enterprise in southwest China (see the following figure), the device is running stably, with a treatment volume of 150t/d, the concentration of ammonia nitrogen in the influent water is 2000-5000mg/L, while the effluent water is stably lower than 5mg/L or less, and the other indexes have reached the contractual assessment requirements. As the project adopts PTFE membrane absorption module, the owner adopts cheap lime instead of liquid alkali to adjust PH in the wastewater pre-treatment section, which greatly reduces the operation cost.