025-5821-8016

PTFE membrane deamination technology instead of blowing off is a new technology combining absorption and membrane separation. The principle of the process is similar to blowing off, first adjust the pH of the wastewater so that most of the ammonia into free ammonia, while using sulfuric acid as an absorbent to absorb the ammonia from the wastewater out of the free ammonia in order to realize the deammonia.

Compared with the blowing off, PTFE membrane deamination microscopic blowing off tower, absorption tower set in one, so in appearance more miniaturized; PTFE membrane deamination blowing off, absorption at the same time, and PTFE deamination membrane is relatively more airtight, also do not need to drum into the air, compared with the blowing off no secondary pollution; PTFE membrane deamination at low pressure, no need for power-consuming equipment such as a blower, more than the blowing off energy-saving obviously.

In addition, due to the PTFE material itself, strong hydrophobic, high strength, corrosion resistance, anti-pollution, so that PTFE deammonia membrane also has a long service life, strong anti-pollution, can be cleaned and regenerated and so on.

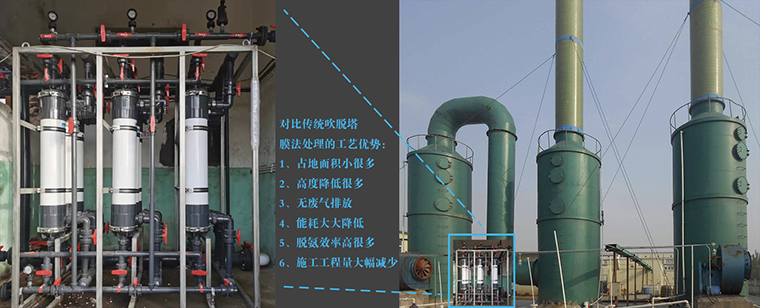

Fig. 1 Comparison sketch of PTFE membrane deammonification and blowing off

Figure 2 Comparison of PTFE membrane deammoniation and blow off physical picture